In this post we have Nish Khanal, Project Manager, share his views on the need for Process Safety and Risk Management and discuss PSM/RMP Program Support from Design Group. PSM/RMP Program at Design Group is designed to help broad range of industries improve operational safety, optimize processes, reduce costs, and comply with the regulators OSHA and EPA.

Why were PSM/RMP programs developed?

Industries that require handling of highly hazardous chemicals are exposed to potential risks of unexpected chemical releases. These incidents pose a significant threat to employees, workplace, community, and environment. OSHA and EPA developed PSM and RMP respectively to minimize the occurrence of such events.

Why is there the need for a dedicated PSM/RMP program?

PSM and RMP are analytical tools focused on preventing the unwanted release of any substance defined as ‘highly hazardous chemical’ by OSHA and “regulated substance” by EPA. The PSM program aims to protect the employees and the workplace, while the RMP program aims to protect the community and environment.

- 29 CFR 1910.119 Process Safety Management (PSM)

In each industry, PSM applies to those facilities/companies that deal with any of more than 130 specific toxic and reactive chemicals over the listed threshold quantities; it also includes flammable chemicals in quantities of 10,000 pounds (4,535.9 Kg) or more.

In each industry, PSM applies to those facilities/companies that deal with any of more than 130 specific toxic and reactive chemicals over the listed threshold quantities; it also includes flammable chemicals in quantities of 10,000 pounds (4,535.9 Kg) or more.

- 40 CFR Part 68 Risk Management Plan (RMP)

In each industry, RMP applies to facilities/companies that holds more than a threshold quantity of more than 250 regulated substance in a process. EPA requires the facility/company to identify potential effect of chemical accident, steps taken to prevent them and emergency response procedure, if needed. These regulated substances are also subject to the requirements of the General Duty Clause. The program requires the facility/company to submit RMP to EPA at least every five years.

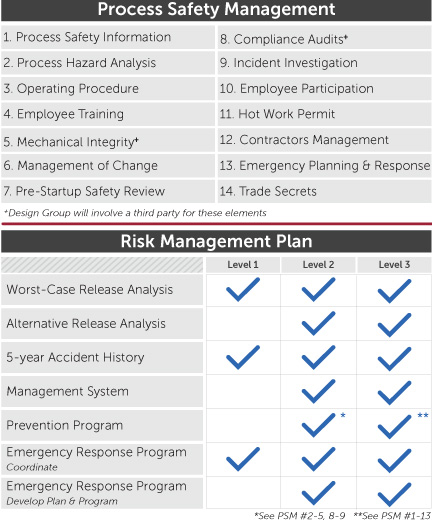

What are the various PSM elements and RMP sections?

What are some of the important timelines to consider for PSM/RMP?

Every 5 Years:

- Risk Management Plans must be revised and resubmitted to EPA

- Offsite Consequence Analysis modelling must be reviewed and resubmitted to EPA

- Process Hazard Analysis must be re-validated

Every 3 Years:

- PSM and RMP Compliance Audits must be completed

- Refresher training must be provided for personnel involved in operating a process

Annually:

- Operating procedures must be certified

Share any recent project experience of PSM/RMP Support.

One of Design Group clients, a natural gas distributor, needed support with updating their PSM/RMP program. Design Group supported the client with maximum intended inventory to determine the applicability of the program. Thereafter, Design Group supported with As-Built walkdowns, simulation development, As-Built drawings, Pressure Safety Value (PSV) Evaluations, Hazardous Area Class Audit and Remediation, Process Hazard Analysis and preparing the Engineering Lists.

We helped the client to follow an aggressive schedule of Process Hazard Analyses and update their PSI on time.

How can Design Group support clients to develop PSM/RMP program?

Navigating the process of PSM/RMP program development and implementation can be overwhelming. Design Group has both knowledge and experience to assist with all levels of PSM/RMP development. We are well-equipped to create high level gap and applicability assessments to identify PSM/RMP site program development.

Our professionals bring industry expertise and provide PSM/RMP compliant solutions, and have assisted many clients, from global corporations to single unmanned sites, with program development and implementations. We work closely with clients to customize programs that meet regulatory requirements along with their internal expectations.

Design Group can help you if you are looking answers for any of these questions and much more…

- Is my entire facility covered by PSM/RMP program?

- We have two processes at two different location of the site. Does it come under PSM/RMP?

- Which RMP Program level does our facility fall under?

- Our site is fully complaint with OSHA’s PSM program. What do we need to do to fully comply with EPA’s RMP program as well?

- Our site has been running safely for last 50 years. Why do I need to spend money on a plant that is already safe?

- Can Design Group develop a software to make one complete platform for our PSM/RMP Program?

- How long will it take for our company to be fully compliant?

We can assist in evaluating and establishing a robust PSM/RMP programs for your facility. Connect with our PSM/RMP experts today.